WAVEX

Weighing and Verification System

"Track what you make, Verify what you ship"

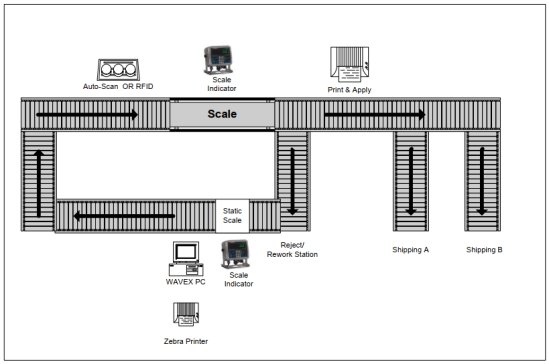

- Static operation on bench scales or floor scales

- In motion operation using in-line conveyor scales

- Product identification by bar-code scan or by production run

Weight verification by product, static and in-motion (conveyor)

- Divert to rework / inspection lane

- Visual accept/reject indication for manual operator sortation

- Divert to shipping lanes according to order or shipper field

Sortation divert control by weight, product SKU, shipper, etc.

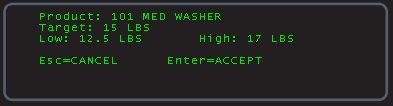

- Configurable product tolerances per SKU/product ID

- Incomplete kit / assembly / pick detection by weight

- Catch shipping errors early when correction is less expensive

Reduce incorrect shipments / Verify package weight and count

- Labels manually or automatically applied

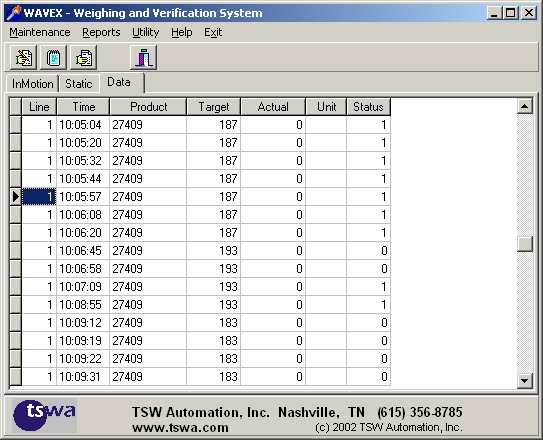

- Flexible query system for all items with given criteria

- Optional scheduled report generation with automatic email send

Bar code labeling / Production reporting / Shipment reporting

- Live or batch product ID/SKU table transfer

- Transfer via LAN / WAN / FTP / email

- Export to Excel, database formats, HTML, ODBC, CSV, flat file

Standalone or interface to WMS / ERP / accounting systems

The WAVEX Weighing & Verification System is designed to check-weigh and ID verify.

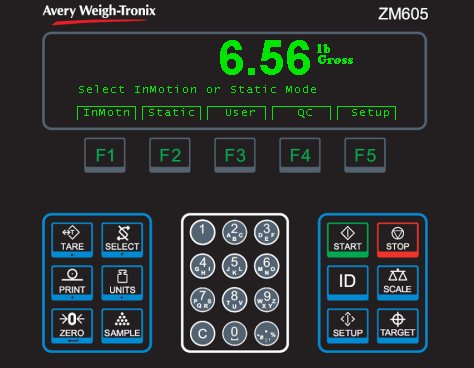

The standard system is designed to work with static or in-motion scales using a scale indicator, and will verify package ID numbers locally or via ODBC to a mainframe.

WAVEX provides real-time tolerance checking with Accept/Reject of finished goods on the production line.

The remote computer screen provides live display of tolerance checks and package ID verifications, displays real-time line graph of actual weights versus target weights, displays running count and average weight of current production run, displays rolling average of the last X number of weighments, and allows for Supervisor to monitor operators progress from PC screen.

A wide variety of standard reports and graphs, selectable by date-range and different sort orders, provides audit trail for quality reporting requirements.