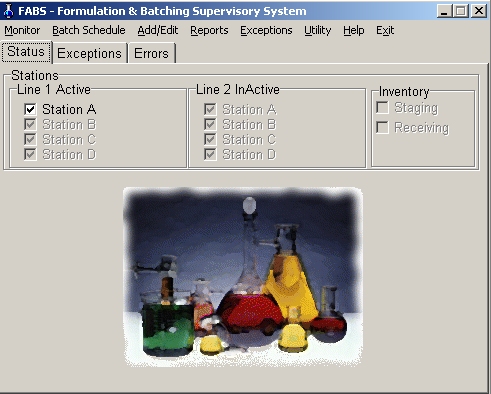

FABS

Formulation and Batching Supervisory System

"Monitor what you make, record what you made"

- Prompts operator through schedule of formulas to be batched

- Enforces ingredient tolerances

- Monitors operator productivity

- Optional clean-out batches minimize cross-contamination

Fast - Accurate Batching

- What ingredients and lots went into a batch?

- Who batched it?

- When was it batched?

- What were the target and actual amounts?

Historical Batch Traceability

- Receives ingredients into inventory

- Depletes inventory as ingredients used

- Tracks vendor lot numbers from start to finish

- View batches for specified lots, formulas, operators, and dates

Track Ingredient Usage

- Ruggedized equipment on the plant floor

- PC stays in the office

- Off-the-shelf standard components

- Modular, easy to maintain design

Designed for the environment

Working in conjunction with a weight indicator and mobile computer station, the FABS Formulation and Batching Supervisory System controls and monitors the manual fill of ingredients into a scale mounted container.

The FABS System consists of two software components. The first program resides in the mobile terminal computer on the factory floor and controls the manual filling of multiple ingredients, by weight, into a container on the scale. The second program resides in a remote PC and monitors the filling operation and collects data from the filling process. The PC program then provides complete record keeping and reporting for management control of the filling process.

The FABS System can accommodate up to two separate filling lines with up to four active filling stations/scales per line. Transactions for all active stations and lines are constantly monitored and recorded at the remote, PC location. The PC operator can watch the results of each filling operation and can modify and download new formulas to each station separately, as the process requires.

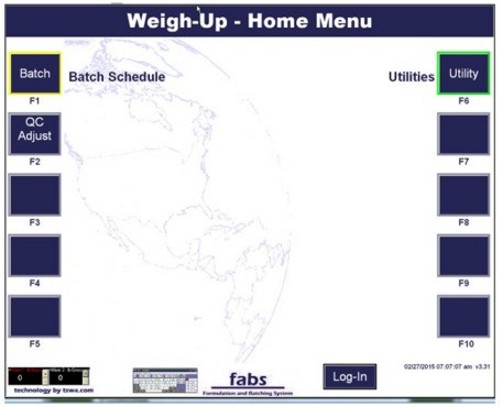

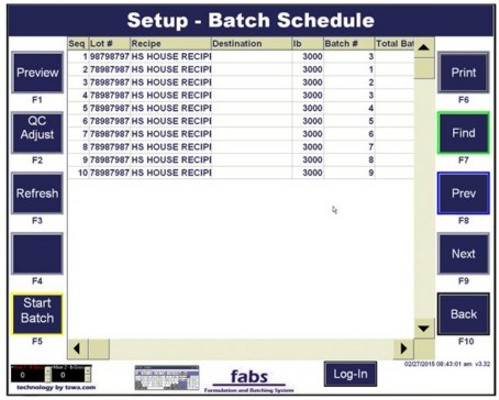

The operator sets up and starts a batching schedule, entering the desired formulas, sequence, and target weight.

The filling station prompts the operator through each stage of the filling process, displaying each formula and the associated ingredients for the formula.

The weight indicator and mobile terminal computer monitor the filling of each ingredient and prevent the operator from under filling or overfilling the ingredient target weight.

The filling station then records the results of each batch and transmits the completed batch information back to the remote PC system.

The unique display of the weight indicator and mobile terminal computer provides the scale operator with detailed and exact information to make the filling process accurate and efficient.